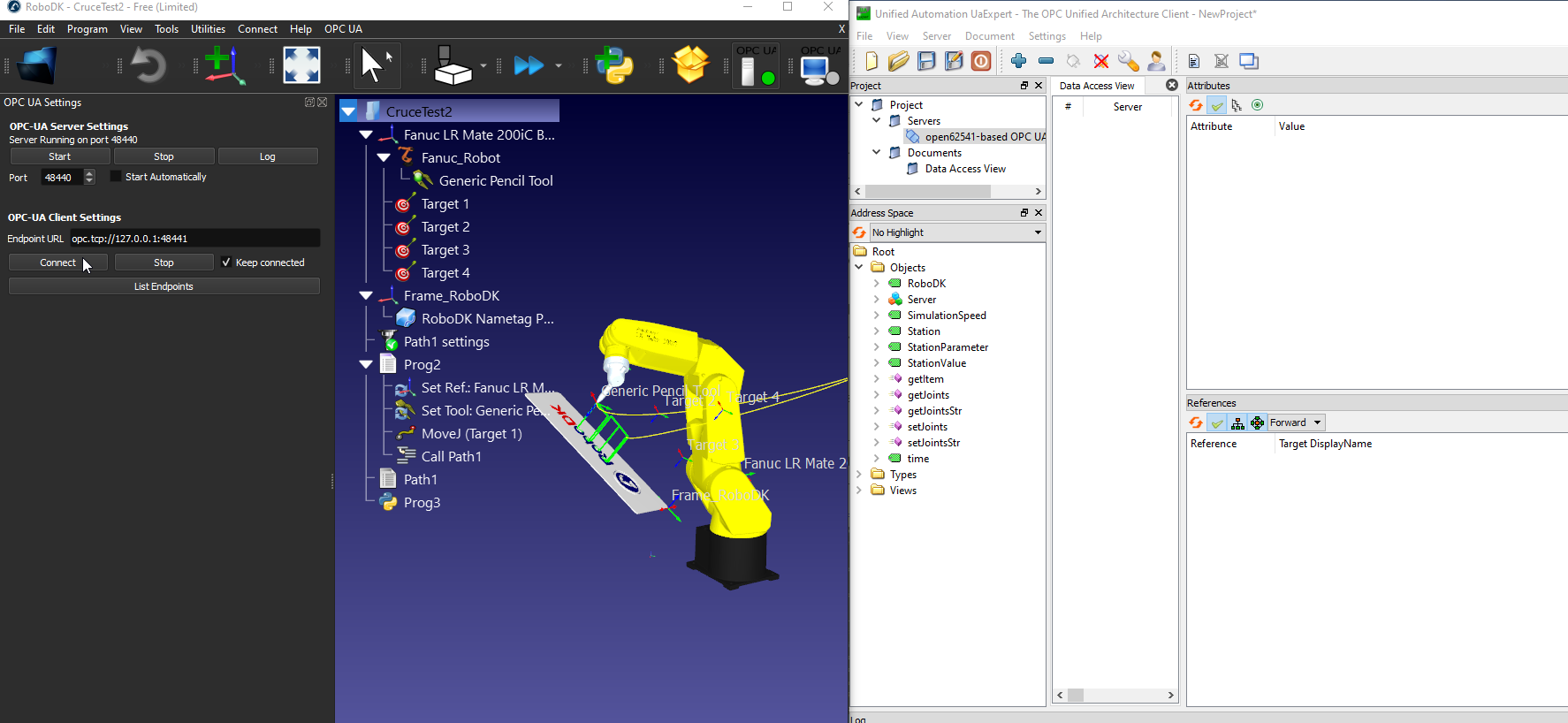

In this example you’ll learn how to enable the OPC UA addin and convert RoboDK into an OPC UA server. We’ll browse some settings by using UaExpert software and Beckhoff TwinCAT3 TF6100.

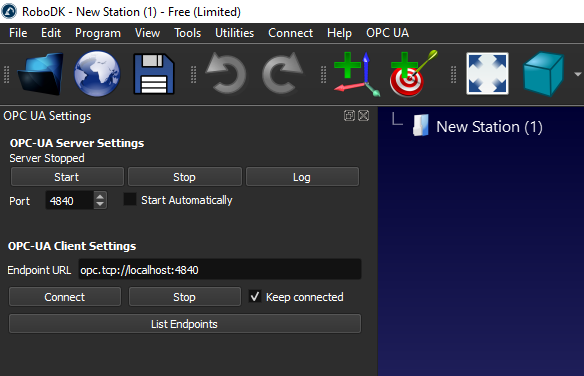

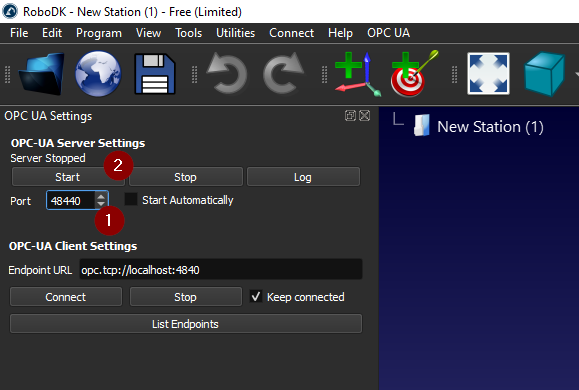

The OPC UA add-in allows you to configure some settings such as the server port. You can also choose to activate the server, deactivate it or automatically start with RoboDK.

With the OPC UA add-in enabled, selectOPC UA-OPC-UA Settingsto configure your OPC UA settings.

OPC UA Settings Screen is shown on the Left side as shown in the following image.

If you see a message such as “RoboDK’s OPC UA server running on port 4840” it means the OPC UA server in RoboDK started.

You can test the OPC UA connectivity with any RoboDK station that has one or more robots.

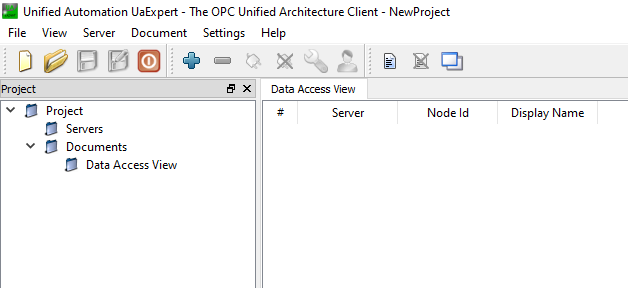

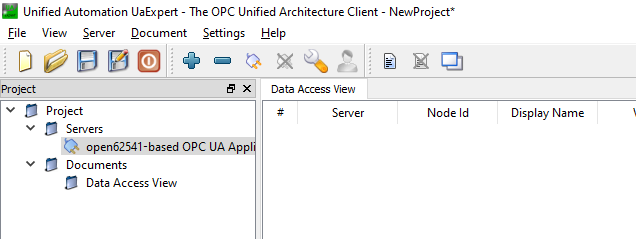

You can use UaExpert software to test the connectivity with the RoboDK OPC UA Server.

You can download the free version of the UaExpert software from the Unified Automation website:https://www.unified-automation.com/downloads/opc-ua-clients.html.

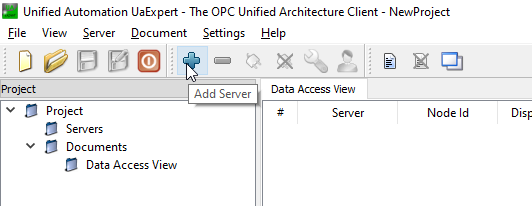

Launch the UaExpert and Click the “+” Button to Add the RoboDK OPC UA Server.

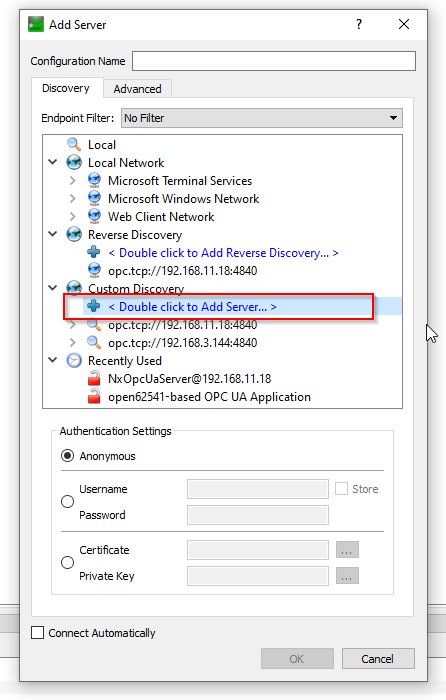

Expand the Custom Discovery and select the

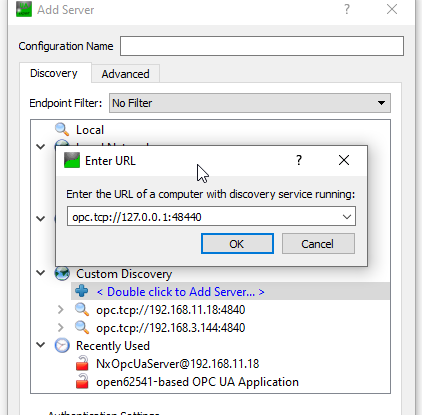

Enter the URL of the OPC UA server, opc.tcp://127.0.0.1:48440 which you configured in the previous step.

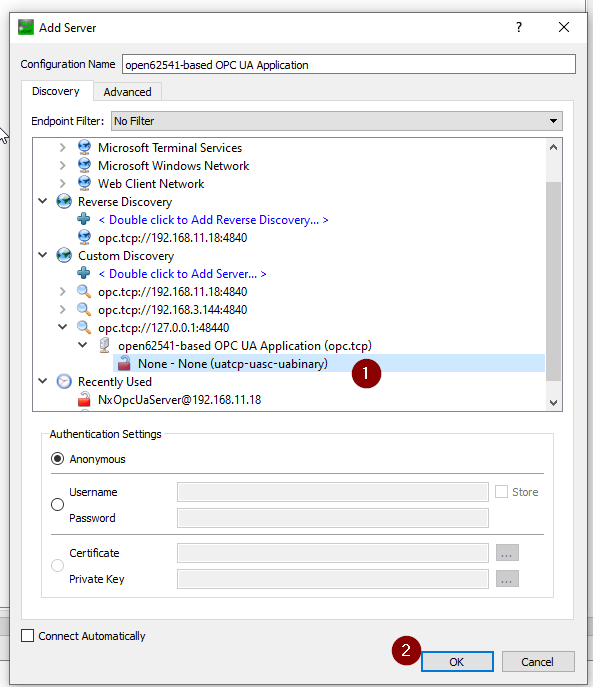

Connect the OPC UA Server with “None” Security.

Server is configured.

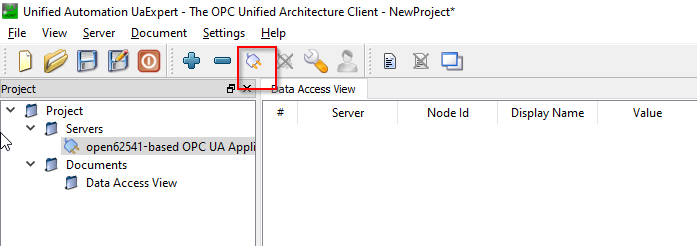

Now you can connect to the RoboDK OPC UA Server from UaExpert.

You can see the Nodes and Methods when the connection is established.

There are some nodes inside the RoboDK OPC UA server to let you exchange some basic information about your station.

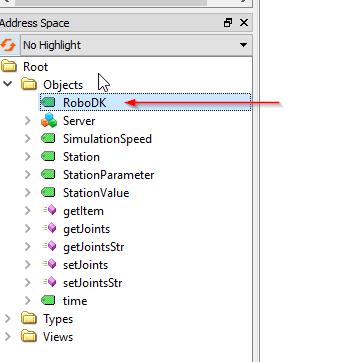

RoboDK节点是一个节点,提供实际的版本sion of your RoboDK Software.

The version RoboDK 64 Bit v5.5.3.23031 was used in this example.

Simulation Speed is a node that shows the actual Simulation Speed and allows the user to overwrite the current Simulation Speed.

The node value is referenced to the Slide bar of simulation speed.

The current Simulation can be read from this node and can overwrite the simulation speed.

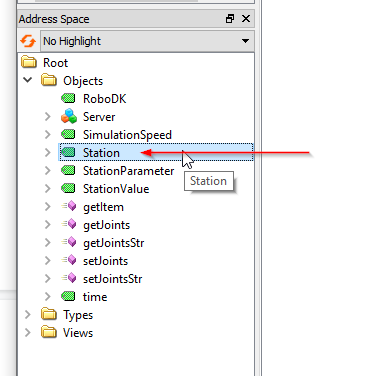

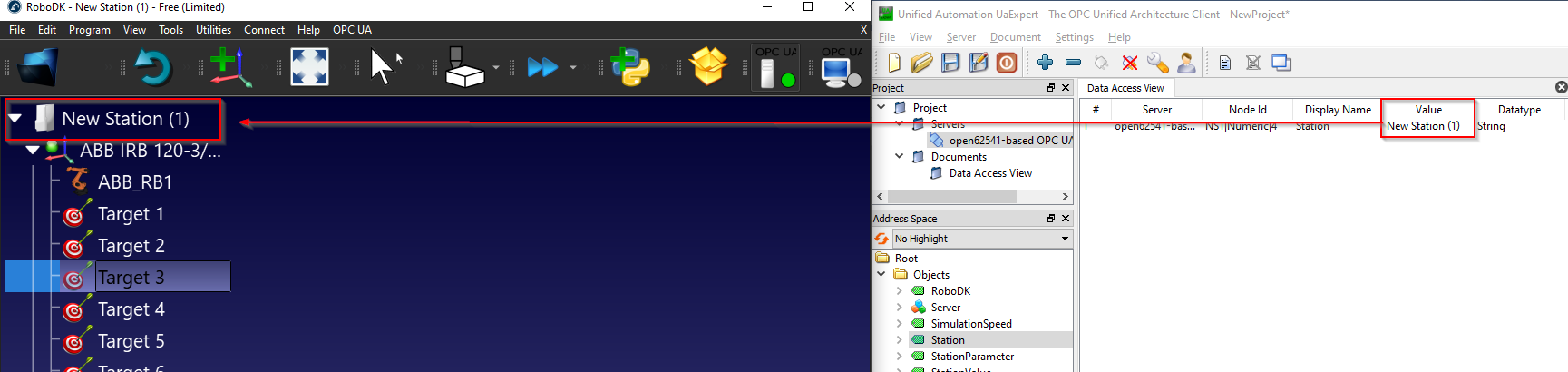

Station Node is a node that allows the user to get the current name of the Station in RoboDK.

As you see below, the Station node is referenced to your “Station Name” in RoboDK.

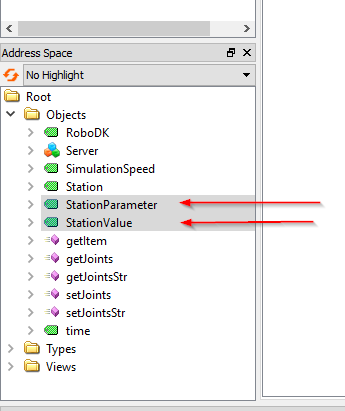

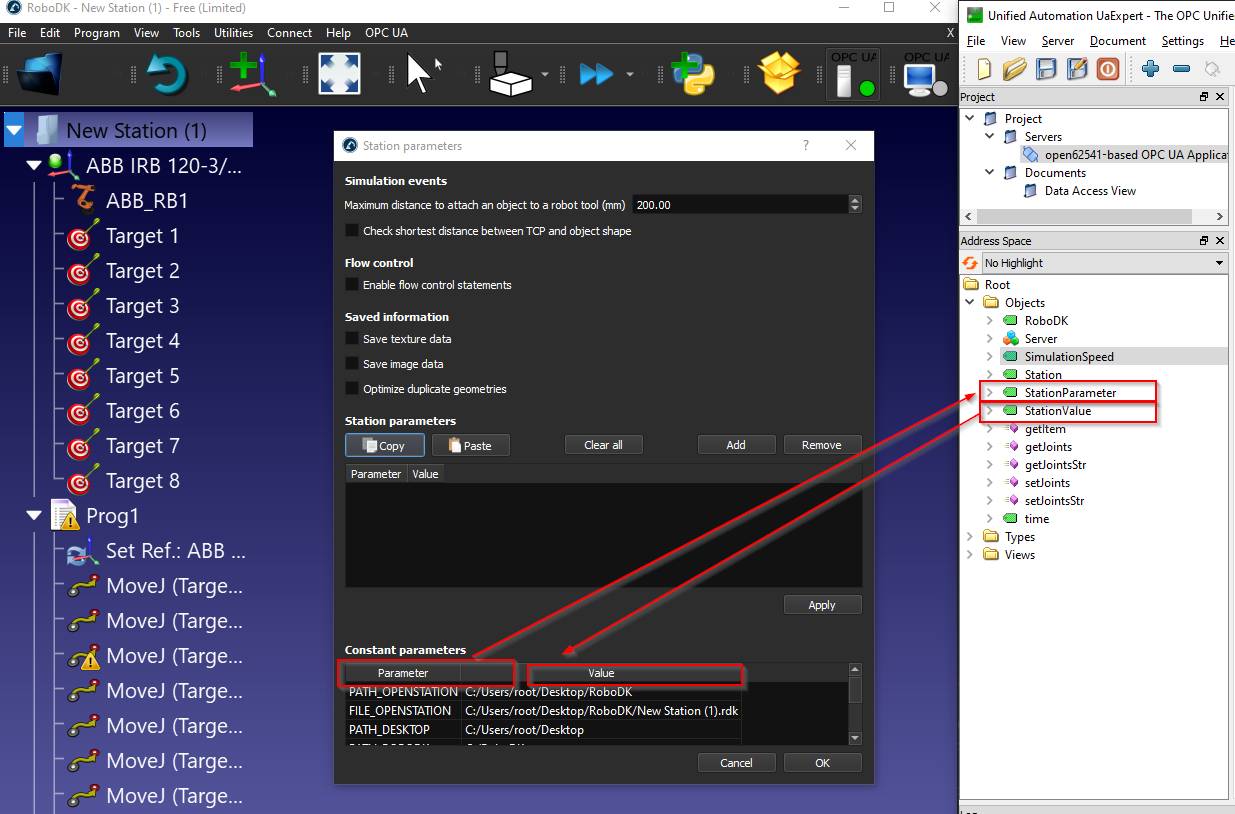

Station Parameter and Station Value are a pair set Node that allows the user to get or set any parameters inside your Station. The RoboDK OPC UA Server will continuously monitor the actual value of “StationParameter” and return the Value of that “StationParameter”, from the Station Value Node.

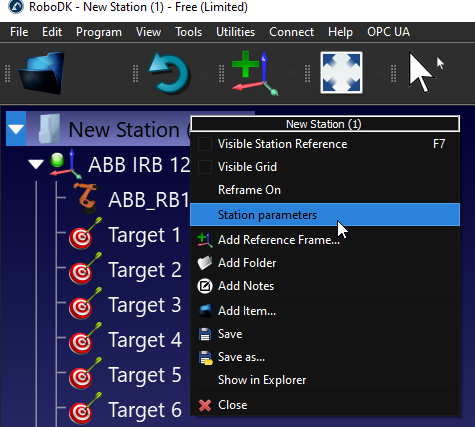

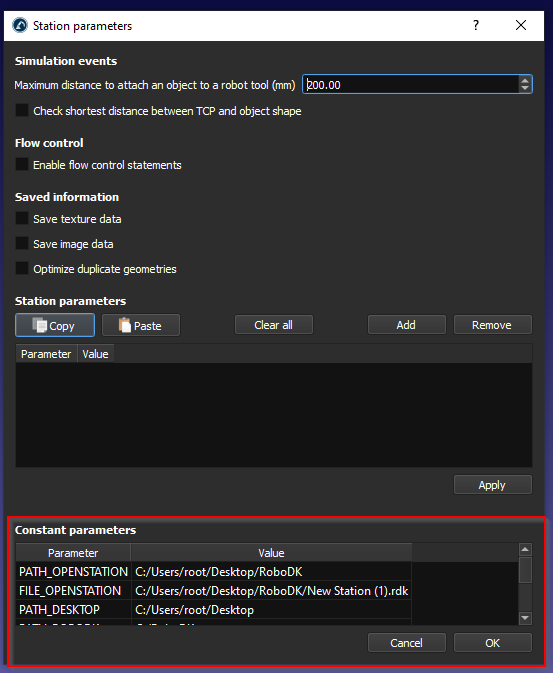

You can view your Station parameters by Right Click your RoboDK Station>Station parameters.

In the Constant parameters field, you can see the default station parameters and their value.

Station parameter is referenced to the “Parameter” field and Station Value is referenced to the “Value” field.

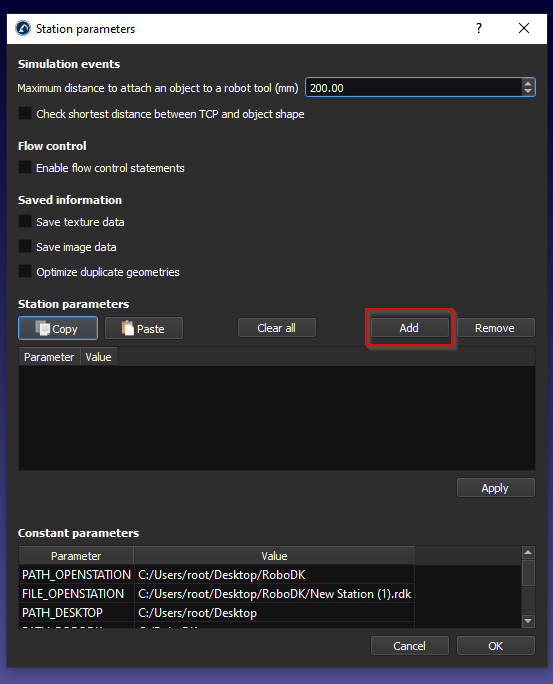

And we can create our own Parameters by clicking the “Add” Button.

A new Station parameter is added.

Enter your Parameter name and the Parameter Value, then press Apply to save it.

You can get your own station parameter as well.

The node time is a node that allows you to get the current time of the RoboDK Station.

A value with DataTime format is returned.

And this Node is updated continually.

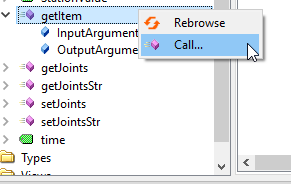

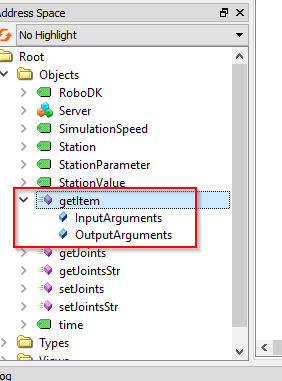

RoboDK OPC UA Server is also provided with some methods to allow the user to access the RoboDK station ‘s Data dynamically.

We can just right click the Method>Call to execute the method.

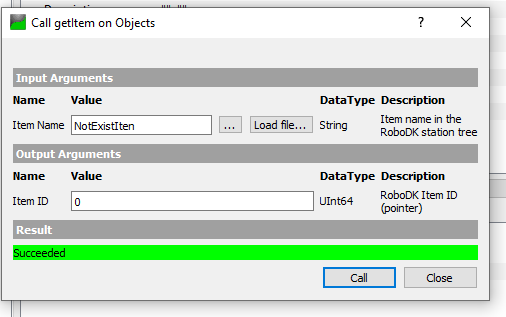

getItem is a Method that allows the user to get the pointer of your Item.

For the InputArguments, Device Name is required, you can image the Device Name is your Station Name,Robot Name..etc.. And Item ID is the OutputArguments that return the Pointer of that Device.

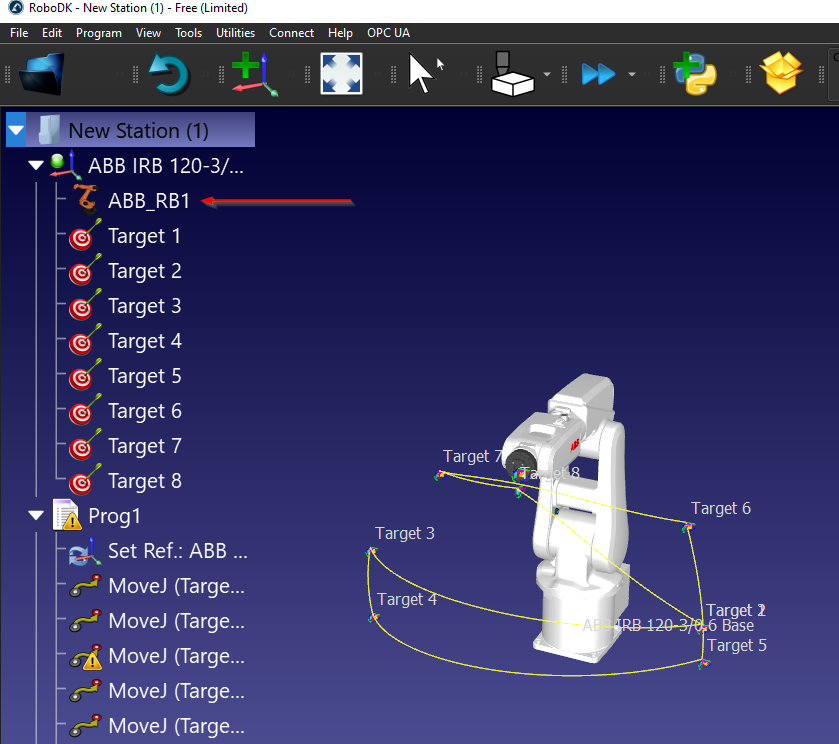

In this Example, I received the Item ID (Pointer) of my ABB Robot that is named as “ABB_RB1”.

0 is returned if the Item Name is invalid or does not exist inside your station.

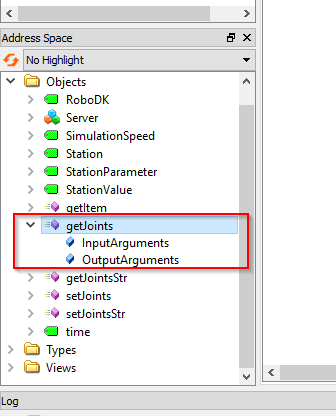

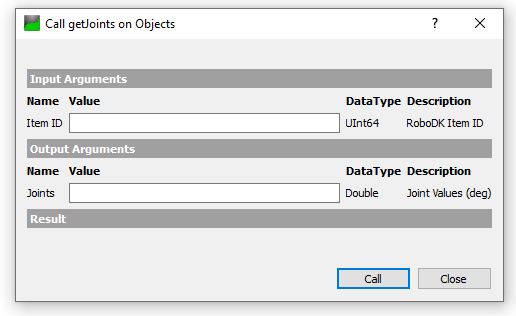

getJonits is a method that allows the user to get the joint value of the robot from the station, based on the Item ID.

The Item ID is the pointer value of your Item, and you can get it from getItem() Method.

We will get the Item ID with this “ABB_RB1” Item name, and a UInt64 value is returned.

关节传递项ID时返回值in the method that we got in the previous.

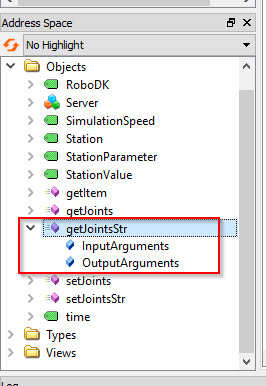

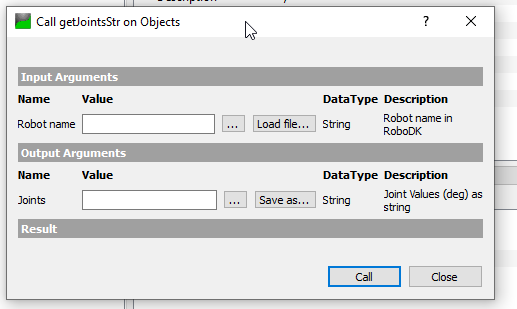

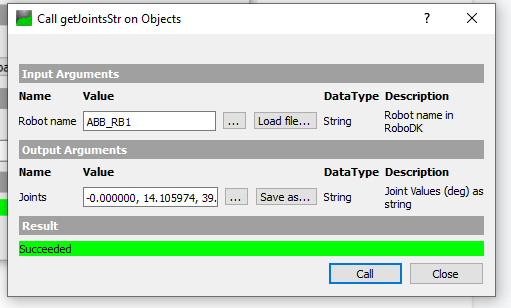

getJointsStr is a method that allows the user to get the Joints value based on a String Value.

We can pass the Robot name (String) in this method.

In My Station, ABB_RB1 is my robot’s name.

We can just pass “ABB_RB1” in the Robot name parameter and call the method - The joint value in String format is returned.

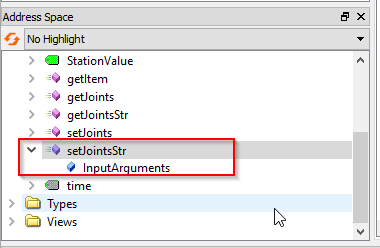

setJointsStr is a method that allows the user to set the Joints value of the Robot, based on a String Value.

In the Robot name, ABB_RB1 is passed, and we can just pass a string with the joint value in the Joints parameter.

For example:-0.000000,0.000000,-0.000000,-0.000000,-0.0,-0.000000

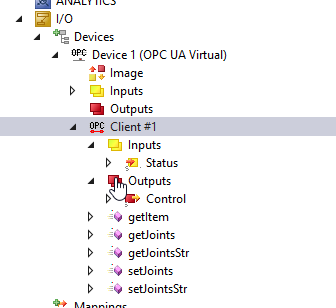

Now we can insert the OPC UA Client by I/O>Devices>Add New Item.

Select Virtual OPC UA Device from OPC >OK.

OPC UA Virtual is inserted.

We need to add an OPC UA Client to access the RoboDK OPC UA Server.

Select Device 1 >Right Click >Add New Item.

Select “OPC UA Client(Module)” and Ok.

OPC UA Client is inserted.

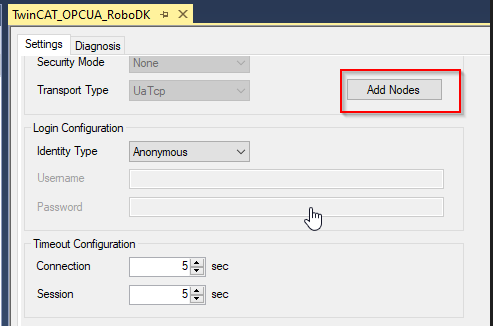

打开OPC UA客户>去设置选项卡>点击the “Select Endpoint” to configure the OPC UA Server endpoint that you would like to access.

Enter the RoboDK OPC UA server URL and Update it.

Press “Add Nodes” to browse the node that is inside the OPC UA Server.

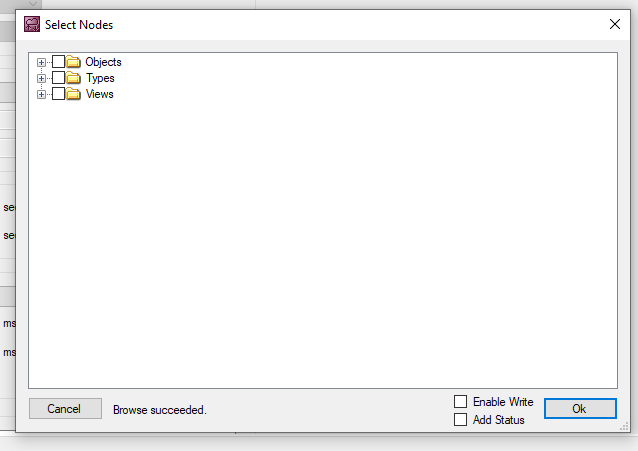

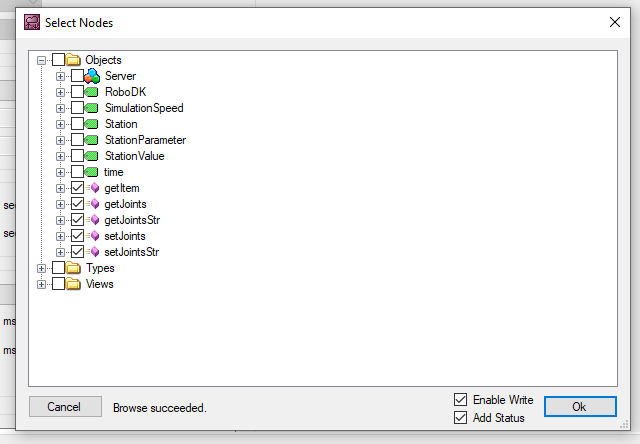

If the connection between TwinCAT and OPC UA Server is established, you can Browse the details of OPC UA server.

Select all Methods and Ok.

Methods are inserted in your Configuration.

Configure your Name Prefix in this field.

Press “Create Plc Code” to create the PLC Code from TwinCAT.

An OpcUaClient folder is created in your project, and all RoboDK Method are created in IEC61131-3 Function Block format.

This section shows a sample program of a Beckhoff TwinCAT PLC that communicates with RoboDK OPC UA server.

PROGRAM MAIN

VAR

bConnected :BOOL;

StationPointer :DINT;

iStep :INT;

bStart :BOOL;;

i :INT;

TON :TON;

bReset :BOOL;

bWrite :BOOL;

TON2 :TON;

bShow :BOOL:=TRUE;

bVis :BOOL:=True;

END_VAR

VAR

Robot_name :STRING(80):='ABB_RB1';

Item_ID :ULINT;

arrJoints :ARRAY[0..11]OF LREAL;

strJoints :STRING(80):='';

arrJointsFromStr:ARRAY[1..11]OF LREAL;

sSeparator :STRING(1) := ',';

arrJointsCommand:ARRAY[1..11]OF LREAL;

strJointsCommand:STRING(80);

END_VAR

VAR CONSTANT

cStepWaitCmd :INT:=0;

cStepInit :INT:=5;

cStepGetItem :INT:=10;

cStepGetItemReset :INT:=20;

cStepGetItemError :INT:=990;

cStepGetJoints :INT:=30;

cStepGetJointsReset :INT:=40;

cStepGetJointsError :INT:=991;

cStepGetJointsStr :INT:=50;

cStepGetJointsStrReset:INT:=60;

cStepGetJointsStrError:INT:=992;

cStepSetJointStrDelay :INT:=69;

cStepSetJointsStr :INT:=70;

cStepSetJointsStrReset:INT:=80;

cStepSetJointsStrError:INT:=993;

cStepEnd :INT:=300;

cStepWaitReset :INT:=999;

END_VAR

VAR

aSplit :ARRAY[1..11] OF STRING(80);

bResultSplit :BOOL;

debug:BOOL;

URL :STRING:='http://192.168.3.42:8091';

END_VAR

bConnected:=OPCUA_VirtualClient_RoboDK_Station.bConnected;

CASE iStep OF

cStepWaitCmd:

IF bStart THEN

iStep:=cStepInit;

bStart:=FALSE;

END_IF

cStepInit:

StationPointer:=0;

FOR i :=1 TO 11 DO

arrJoints[i]:=0.0;

arrJointsFromStr[i]:=0.0;

aSplit[i]:='';

END_FOR

IF NOT OPCUA_VirtualClient_RoboDK_Station.getItem.bBusy

AND NOT OPCUA_VirtualClient_RoboDK_Station.getItem.bError

AND NOT OPCUA_VirtualClient_RoboDK_Station.getJoints.bBusy

AND NOT OPCUA_VirtualClient_RoboDK_Station.getJoints.bError

AND NOT OPCUA_VirtualClient_RoboDK_Station.getJointsStr.bBusy

AND NOT OPCUA_VirtualClient_RoboDK_Station.getJointsStr.bError

AND NOT OPCUA_VirtualClient_RoboDK_Station.setJoints.bBusy

AND NOT OPCUA_VirtualClient_RoboDK_Station.setJoints.bError

AND NOT OPCUA_VirtualClient_RoboDK_Station.setJointsStr.bBusy

AND NOT OPCUA_VirtualClient_RoboDK_Station.setJointsStr.bError

THEN

iStep:=cStepGetItem;

END_IF

iStep:=cStepGetItem;

cStepGetItem:

IF OPCUA_VirtualClient_RoboDK_Station.getItem.bDone THEN

iStep:=cStepGetItemReset;

Item_ID:=OPCUA_VirtualClient_RoboDK_Station.getItem.Item_ID;

ELSIF OPCUA_VirtualClient_RoboDK_Station.getItem.bError THEN

iStep:=cStepGetItemError;

END_IF

cStepGetItemReset:

IF NOT OPCUA_VirtualClient_RoboDK_Station.getItem.bError

AND NOT OPCUA_VirtualClient_RoboDK_Station.getItem.bBusy

THEN

iStep:=cStepGetJoints;

END_IF

cStepGetJoints:

IF OPCUA_VirtualClient_RoboDK_Station.getJoints.bDone

AND NOT OPCUA_VirtualClient_RoboDK_Station.getJoints.bBusy

THEN

iStep:=cStepGetJointsReset;

ELSIF OPCUA_VirtualClient_RoboDK_Station.getJoints.bError THEN

iStep:=991;

END_IF

cStepGetJointsReset:

IF NOT OPCUA_VirtualClient_RoboDK_Station.getItem.bError

AND NOT OPCUA_VirtualClient_RoboDK_Station.getItem.bBusy

THEN

iStep:=cStepGetJointsStr;

END_IF;

cStepGetJointsStr:

IF OPCUA_VirtualClient_RoboDK_Station.getJointsStr.bDone

AND NOT OPCUA_VirtualClient_RoboDK_Station.getJointsStr.bBusy

THEN

iStep:=cStepGetJointsStrReset;

ELSIF OPCUA_VirtualClient_RoboDK_Station.getJointsStr.bError THEN

iStep:=cStepGetJointsStrError;

END_IF

cStepGetJointsStrReset:

IF NOT OPCUA_VirtualClient_RoboDK_Station.getJointsStr.bError

AND NOT OPCUA_VirtualClient_RoboDK_Station.getJointsStr.bBusy

THEN

iStep:=cStepSetJointStrDelay;

END_IF;

cStepSetJointStrDelay:

strJointsCommand:=''; strJointsCommand:=CONCAT(LREAL_TO_STRING(arrJointsCommand[1]),strJointsCommand);

strJointsCommand:=CONCAT(strJointsCommand,',');

strJointsCommand:=CONCAT(strJointsCommand,LREAL_TO_STRING(arrJointsCommand[2]));

strJointsCommand:=CONCAT(strJointsCommand,',');

strJointsCommand:=CONCAT(strJointsCommand,LREAL_TO_STRING(arrJointsCommand[3]));

strJointsCommand:=CONCAT(strJointsCommand,',');

strJointsCommand:=CONCAT(strJointsCommand,LREAL_TO_STRING(arrJointsCommand[4]));

strJointsCommand:=CONCAT(strJointsCommand,',');

strJointsCommand:=CONCAT(strJointsCommand,LREAL_TO_STRING(arrJointsCommand[5]));

strJointsCommand:=CONCAT(strJointsCommand,',');

strJointsCommand:=CONCAT(strJointsCommand,LREAL_TO_STRING(arrJointsCommand[6]));

TON2(IN:=TRUE,PT:=T#0.2S);

IF TON2.Q THEN

TON2(IN:=FALSE);

iStep:=cStepSetJointsStr;

END_IF

cStepSetJointsStr:

IF (

OPCUA_VirtualClient_RoboDK_Station.setJointsStr.bDone

AND NOT

OPCUA_VirtualClient_RoboDK_Station.setJointsStr.bBusy

)

OR NOT bWrite

THEN

iStep:=cStepSetJointsStrReset;

ELSIF OPCUA_VirtualClient_RoboDK_Station.setJointsStr.bError

THEN

iStep:=cStepSetJointsStrError;

END_IF

cStepSetJointsStrReset:

bWrite:=FALSE;

OPCUA_VirtualClient_RoboDK_Station.setJointsStr.bExecute:=FALSE;

IF NOT OPCUA_VirtualClient_RoboDK_Station.setJointsStr.bError

AND NOT OPCUA_VirtualClient_RoboDK_Station.setJointsStr.bBusy

THEN

iStep:=cStepEnd;

END_IF;

cStepEnd:

TON(IN:=TRUE,PT:=T#0.1S);

IF TON.Q THEN

TON(IN:=FALSE);

IF NOT debug THEN

iStep:=10;

ELSE

iStep:=cStepSetJointStrDelay;

END_IF;

END_IF

cStepGetItemError:

Item_ID:=0;

iStep:=cStepWaitReset;

cStepGetJointsError:

FOR i :=0 TO 11 DO

arrJoints[i]:=-99999.99;

END_FOR

iStep:=cStepWaitReset;

cStepGetJointsStrError:

strJoints:='';

iStep:=cStepWaitReset;

cStepWaitReset:

IF bReset THEN

iStep:=cStepInit;

bReset:=FALSE;

END_IF;

END_CASE

aSplit[1] := strJoints;

FOR i:=1 TO 7 DO

bResultSplit := FindAndSplit(

pSeparator := ADR(sSeparator)

,pSrcString := ADR(aSplit[i])

,pLeftString:= ADR(aSplit[i])

,nLeftSize := SIZEOF(aSplit[i])

,pRightString:= ADR(aSplit[i+1])

,nRightSize := SIZEOF(aSplit[i+1])

,bSearchFromRight := FALSE );

IF NOT bResultSplit THEN

EXIT;

END_IF

END_FOR

FOR i :=1 TO 6 DO

arrJointsFromStr[i]:=STRING_TO_LREAL(aSplit[i]);

END_FOR;

//

OPCUA_VirtualClient_RoboDK_Station.getItem(

bExecute:=iStep=cStepGetItem

,Item_Name:=Robot_name

);

OPCUA_VirtualClient_RoboDK_Station.getJoints(

bExecute:=iStep=cStepGetJoints

,Item_ID:=Item_ID,Joints=>arrJoints

);

OPCUA_VirtualClient_RoboDK_Station.getJointsStr(

bExecute:=iStep=cStepGetJointsStr

,Robot_name:=Robot_name,Joints=>strJoints

);

IF bWrite THEN

OPCUA_VirtualClient_RoboDK_Station.setJointsStr(

bExecute:=TRUE

,Robot_name:=Robot_name,Joints:=strJointsCommand);

END_IF;